| I hope this message finds you well. I am writing to emphasize the critical importance of employee health and hygiene in maintaining the highest standards of food safety within your establishment. During my Food Safety trainings I often ask, “How many people have had an official employee illness training outside of taking this training? “. The answer is astonishingly low. Ensuring the well-being of your employees directly correlates with the safety and quality of the food you serve. The FDA has a comprehensive Handbook to address best practices. The handbook is now accessible on our website MarylandFoodHandler.com . It covers essential topics such as proper handwashing techniques, illness reporting procedures, and personal hygiene standards that are crucial for preventing foodborne illnesses and maintaining compliance with regulatory requirements. We encourage you to share this resource with your team managers and integrate its recommendations into your daily operations. By prioritizing employee health and hygiene, we collectively contribute to a safer and healthier environment for both your staff and your customers. Should you have any questions or require further assistance, training, or any other food safety concerns, please do not hesitate to contact me. I am here to support you in upholding the highest standards of food safety. Thank you for your attention to this matter. Together, we can continue to raise the bar for food safety excellence. Sue Farace, CP-FS |

Category Archives: food safety

ServSafe Food Protection Manager Certification

We are happy to announce that Brightview Sr Living in Perry Hall will be hosting a training once a month for the remainder of the year. If you would like to host a training at your facility you can enroll one student for FREE!

Our next open enrollment training and exam will be held June 17th at 9 AM. You can register here

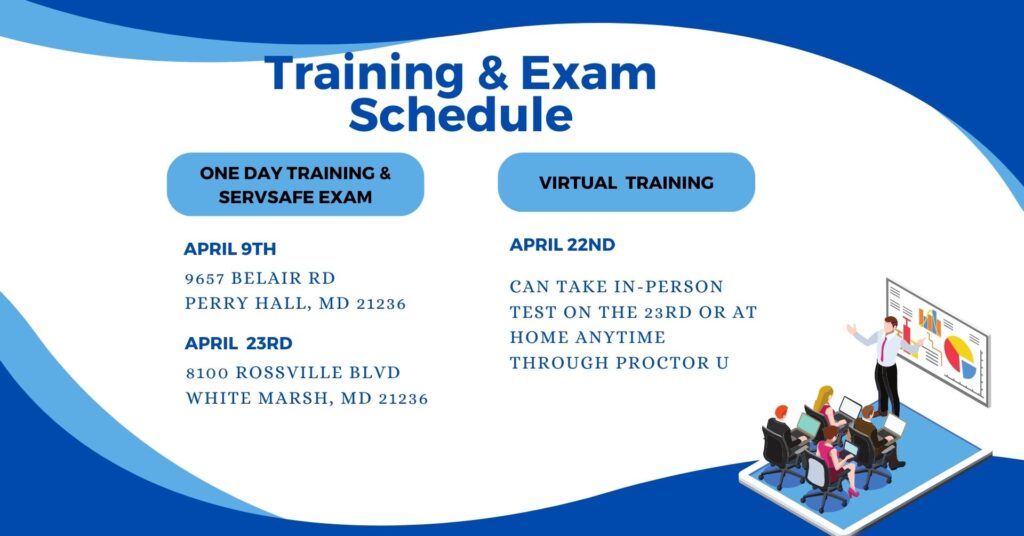

April 2024 Food Protection Training Schedule

April 22, 2024 Virtual training through Zoom. You will need to take the exam in person or through ProctorU. When you register for both the training and an in-person exam the cost is $145 per student

April 23, 2024 In person training and computer ServSafe Exam.

Check our schedule for May and June trainings: https://www.marylandfoodhandler.com/food-safety-training-schedule.php

Food Protection Manager Training

I receive quite a few inquiries asking about the difference between the Food Protection Manager Certification training and food handler training. The clearest difference is if you are located in one of the following Maryland Counties; Baltimore (County or City), Prince Georges, Montgomery, or Howard you must have one person that is certified by passing an approved exam such as ServSafe® on duty at all times when food is being handled.

During the class that prepares you for the exam you will learn;

- How to serve safe food

- Learn about bacteria, viruses, parasites, fungi and biological toxins.

- What can cause food to become contaminated or adulterated

- How to protect food from contamination

- Discussion on food allergies

- Personal hygiene

- Temperature control from delivery to sale

- Facility and pest management

- Employee training

- Introduction to Food Safety Management Plans

Our Top-Notch training is for all staff that work with or around food and will provide staff knowledge they need to provide safe food and includes the following topics:

- Why practicing food safety is important

- How to handle food during the flow of food

- What can go wrong, and the cost to the employees and owners

- How food handlers can prevent contamination of the food they serve

- Allergens

- Employee Illness

For more information on which training would be best for your staff, call our office at 410-687-1015 and we will be happy to help.

You can also find our current training schedule at https://www.marylandfoodhandler.com/food-safety-training-schedule.php

Reduced Oxygen Packaging: Are you doing it correctly?

Reduced Oxygen Packaging (ROP) is a process used in packaging food to extend its shelf life, as well as retard and control microbial growth in foods, it is also used for quality control issues. However, it is crucial to note that ROP can be dangerous if not done correctly. Two pathogens, clostridium botulinum and listeria monocytogenes, are of particular concern when oxygen is removed or decreased dramatically from foods. This creates an environment for these bacteria to grow, possibly leading to the formation of toxins or spores, which cannot be killed during the cooking step. To mitigate these risks, a retailer must have a Hazard Analysis and Critical Control Points (HACCP) plan in place before any ROP takes place. The plan should include identifying the risks, critical control points, critical limits, monitoring, corrective actions, verification, record keeping, and labeling of the foods. Proper temperature control is the primary barrier to control the risks.

Unfortunately, in recent years, many facilities have been packaging food using ROP, Vacuum Sealing, or Sous Vide cooking without proper knowledge. This poses an unnecessary risk to the consumer and can cost the facility. The most common mistakes I have come across while working with clients include:

• Using a vacuum sealer on fish that is not frozen first – Fish must be frozen before, during, and after packaging. It is also not allowed to package a product containing fish for Sous Vide cooking or use the cook > chill process for items containing fish.

• Caterers often use ROP for ease of transporting food. Often, the process used is Cook > Cool > Cold Hold >Package using a vacuum sealer. This is not allowed. The proper process is Cook > Package > Cool (chill) > Cold Hold.

• Repackaging soft cheeses to extend the life of the cheese. This is only allowed for hard cheeses, and one must have knowledge of what a hard cheese is.

• Cooked seafood, such as crab cakes, cannot be reduced oxygen packaged under any circumstances.

• Using sous vide cooking without having a self-sealing thermometer to ensure temperatures are being met.

There are other guidelines that must be followed, and the State of Maryland has an easy-to-understand document entitled “Reduced Oxygen Packaging at Retail” available for download here

If you are currently doing any Reduced Oxygen Packaging and it is not part of your HACCP plan, call us at 410-687-1015 today, and we can help you become compliant.

Why are so many foods containing Bio-Engineered Ingredients?

Recently my social media feed has been bombarded with memes, Reels, and TikTok’s, about food labeled “Bio-Engineered food”. Most of us have been consuming BE foods for a while. The food ingredients haven’t changed, but the labeling has.

Congress passed the National Bioengineered Food Disclosure Standard, requiring manufacturers to disclose when an ingredient is a Bioengineered food (BE). BE foods were previously referred to as GMO (genetically modified organism). The mandatory compliance date for manufacturers was January 1, 2022.

Labeling has made consumers more aware of what they are eating and because of social media, awareness is heightened. The question is are BE foods safe to consume? The answer is, it depends on who you ask.

The USDA, FDA, WHO, and most scientists agree that there is no clear evidence that BE foods are harmful. In fact, in GMOs 101: Your Basic Questions Answered, The USDA answers the question, “Do GMO’s affect your health?”, the answer is, “GMO foods are as healthful and safe to eat as their non-GMO counterparts. Some GMO plants have actually been modified to improve their nutritional value. “

However, concerns have been raised that BE foods can cause antibiotic resistance, environmental risks from cross-pollination, change in nutritional values, or even toxicity. Another concern is when two foods are genetically modified and one contains an allergen, the allergen can be transferred through the DNA.

This does raise the question of, if they are safe, why require disclosure?

What are BE foods as determined by the USDA Agricultural Marketing Services (AMS)? Alfalfa, Apples, Canola, Corn, Cotton, Eggplant, Papaya, Pineapple, Potato, Salmon, Soybean, Squash (summer), and Sugar beets. These foods can also be found in Non-BE varieties, more details on specific varieties are available on the AMS website.

When the BE varieties of these foods are included as an ingredient in a manufactured food the BE statement must be present. However, not every manufactured product that contains a BE food is subject to the guidelines of the Standard. This is where it can get complicated.

Simple answer: If meat, poultry, or eggs are a predominant ingredient the food may not be subject to the Standard, and disclosure may not be required.

Technical answer: If the first ingredient is subject to the Federal Meat Inspection Act, (meat, poultry, or eggs) the food would not be subject to the Standard. If the first ingredient is broth, stock, or water and the second ingredient is subject to the Federal Meat Inspection Act, the food would not be subject to the Standard.

In conclusion, just because it does not say “contains BE ingredients”, does not mean there are none. If you do not want to consume BE foods, the only way to be 100% sure is to eat organic foods.

For extra fun reading, here is the link for standard: https://www.ams.usda.gov/sites/default/files/media/Final%20Bill%20S764%20GMO%20Discosure.pdf

Are you playing Wacka-Mole?

How many owners and managers have watched one of the restaurant “rescue” shows and thought what a crock. Reality TV is not so real and most changes they make are unrealistic to maintain. That doesn’t mean that an underperforming restaurant can’t improve with professional advice. SMF Training and Consulting wants you to succeed and flourish and I will work hard to provide you with the best service and tools to help you reach your goals.

The restaurant industry has never been an easy one. With COVID-19, owners and managers are struggling more than ever to reach goals or even keep the doors open. Don’t wait until you are at the point of grasping at new ideas just to get a handful of customers through the door. That will not sustain you through these rough times. Every owner needs to maximize every part of the business. Sometimes it is hard to see or admit what needs to be fixed from inside the operation. I have what it takes to understand the organization from top to bottom, inside and out. If you feel like you are playing wacka-mole everyday and struggling to get customers in your door, give us a call today we can help.

What is the process?

- FREE CONSULTATION – First we start off with a free on-site* consultation to review your goals and concerns. I want to hear from the you about what is working and what isn’t. I will ask questions about the existing business model, goals (current and future), what you feel your challenges are. This is your business and vision and your financial stake is on the line. I am not here to rebrand you with my vision.

- Assessment – Based on what I learned in our first visit, I will provide a basic assessment on what areas SMF Training and Consulting can help and will provide you with a quote for services.

- Observation – Observing the operation is the best way to see what is going on. This will include back of the house, front of the house, and general organization. Guest experience will be monitored. Existing management plans will be reviewed. If permitted, anonymous interviews with staff will be conducted.

- Recommendations – Based on your objectives and my observations, I will provide a comprehensive recommendation report (CRR) on steps that can be taken to help you reach your goals.

- Review – The CRR will be reviewed and we will meet with key staff so they understand what needs to be done. Staff must get behind the improvements.

- Implementation – We will work together to implement the new plan, re-train staff as necessary and monitor the success.

About the owner, Sue Farace, CP-FS; I worked in the construction industry as an accountant / business manager for 13 years. I left the corporate world in 1997 and broke into the hospitality industry as an owner operator of several food service facilities. I oversaw the planning, development and construction of 3 of my facilities. I have been a consultant for the last 10 years completing a wide range of projects. You can read more about my background here.

*Travel charges may apply outside of 25 miles from zip code 21224

Do you have a positive food safety culture?

When I was a teenager, I worked at a large franchise fast food place. I remember one night while closing the assistant manager told me to take the leftover toppings from the salad bar and pour them back into the original container. Even my 16-year-old self knew that was wrong and it sent a message to me that the rules don’t matter.

When top management puts profits over food safety and quality control, they are putting the customer last. The staff see this and take the attitude of “If they don’t care, why should I”. Without a positive food safety culture, employees can get frustrated at the lack of leadership, customer service suffers, quality control does not exist and customers stop coming in the front door.

A positive food safety culture starts at the top and flows on down to the staff that grind out every day getting it done. When the owners, general managers and top staff create an environment focused on food safety and quality control the staff can work more efficiently. When there is a plan with expectations the staff understand what is expected of them and the staff work more like a team. Happy Team – Happy Customer.

Let’s talk about what we can do to develop a Positive Food Safety Culture in your facility.

You do not need to recreate the wheel. If you are a Maryland facility, you already have a written HACCP plan and that should be an excellent framework to build upon. However, if it is sitting on the shelf gathering dust it is not serving any purpose. Go get that HACCP plan, dust it off and let’s get to work.

First things first, let’s assess the current systems in place. I have created a list of questions you should ask yourself.

- Do you make Food Safety a priority in your restaurant?

- If you thought, well yes, of course we do. What do you specifically do to communicate that to your staff?

- Does the existing HACCP plan represent your current menu?

- Are the SOP’s a reflection of the current processes and procedures currently in use?

- Do the SOP’s include the written policy, monitoring, corrective actions and verification steps?

- Are the food process charts or recipe cards written in a clear understandable way so that employees can follow them? Are they being used, especially by new staff?

- What is the current status of the restaurant?

- Take inventory of where deficiencies are noted by past local health inspection and perform an in-depth inspection of the facility. Depending on the size of your facility, 0ur 3rd party inspection checks for over 300 line items and rates them. Providing you with a snapshot of how your facility is doing.

- Check all the online rating services like Google & Yelp. Do you see similar complaints over and over?

- What are the current employee training methods?

- Are they verbal, written, a computer or video-based learning system?

- Do they seem to be effective?

- Are some of your complaints or health department deficiencies directly related to an employee not following company standards or violating food safety laws?

- How is your current communication between management and staff?

- Does staff feel comfortable informing you of potential problems?

- Do staff work as a team or is it every person for themselves?

- Do managers often say they feel like they are playing wack-a-mole?

- Do you have regular staff meetings with and without managers?

After answering these questions do you still feel like you have a positive food safety culture that focuses on providing the best experience for your customer? Not to worry, we can help you work though the challenges that your facility faces. SMF Training & Consulting can work with you to establish a working Food Safety Management System where the focus will be on providing safe food and excellent quality control. We will work within your budget to get you where you need to be for the best customer experience. Give us a call today for a free 1-hour consultation.

The risk of third party delivery services

The problem:

The driver opens up the to go container to take a peak or worse a sampling of the food. By touching it, they could contaminate the food with bacteria or viruses, physical contamination could occur, or worst-case deliberate contamination such as spitting on the food.

In a study done by US Foods they found that 28% of drivers admit to taking food out from an order. A quick search on the internet about this occurring and there are several cases. Vanessa Harrell, posted on Facebook that an UBER Eats driver ate some of her food! She was a regular patron and knew what the food should look like.

The Solution:

Use delivery bags that are tamper resistant like those pictured here. As an alternative  you can seal each individual container with a tamper evident sticker, label or tape. However, there have been several reports where from condensation the sticker “comes off” or “becomes loose” when attaching directly to the product container. Do not use anything that can be easily recreated by the driver, like staples. Notify the customer on the receipt or bag what they should look for so the driver can’t switch bags. Also, make sure that before you seal the bag that all utensils, condiments and napkins are already included inside.

you can seal each individual container with a tamper evident sticker, label or tape. However, there have been several reports where from condensation the sticker “comes off” or “becomes loose” when attaching directly to the product container. Do not use anything that can be easily recreated by the driver, like staples. Notify the customer on the receipt or bag what they should look for so the driver can’t switch bags. Also, make sure that before you seal the bag that all utensils, condiments and napkins are already included inside.

The Real Cost:

Imagine, a customer getting food and thinking the portion was small? Not complaining, just not returning for more business?

You cannot control the quality of the food when it leaves your door, but if using delivery services, you must do what you can to protect it. The driver, who might have little or no food service experience is now in charge of food safety and quality for your brand. Food may get cold or dropped. In the picture to the left, the driver took a delivery bag into the bathroom stall while doing his “business”.

Before signing up for a third-party service that claims increased sales, you should think about what the real cost is. The fees of 20-30% of sale price cut into profits and quality control issues that could cause harm to your brand. It might not be worth the increased sales to your bottom line.

Selling homemade goods using cottage food laws

Do you make a great cookie or tasty home-baked bread? Do your friends and family always ask you to decorate cakes for them?

Do you make a great cookie or tasty home-baked bread? Do your friends and family always ask you to decorate cakes for them?

Have you ever thought about starting your own business from home? You can have up to $25,000 in sales a year and not need a health permit. Effective October 1, 2019 there is even a pathway for you to sell to retail stores! There are a few things you need to know first before getting too excited.

You need to understand the Cottage food industry laws in Maryland. There are some limits on what you can make in your home kitchen. Some of the foods you can not sell include; Jerky made from meat products, chocolate covered strawberries, cut fruit displays, cupcakes with buttercream icing and fruit pies. You can sell items like; cookies, chocolate covered pretzels, breads and cakes without potentially hazardous toppings or fillings. Potentially Hazardous means they need refrigeration.

You must label your items properly. For instance you must have the list of ingredients and a statement saying “made by a cottage food business that is not subject to Maryland food safety regulations”. Your sales also must only be in the state of Maryland. That includes mailing orders outside the state.

You should also have a good knowledge of food safety. This can be achieved by taking a food protection manager training. The one day class is $145 and I bet your customers would be happy to know you have been properly trained in how to protect the food from contamination! You can even post your official ServSafe certificate on your page!

If you want to learn more about the specific restrictions you can find them by clicking the Cottage Law link. We are always happy to answer your questions so feel free to call the office at 410-687-1015.

Have a food safe day!

Sue