In the food industry, there’s an old debate: Is it better to play by the rules, or to take action and ask forgiveness later?

I’ve seen both. As a consultant, I’ve worked with businesses that invested thousands of dollars into equipment, construction, and operations — all before securing the right permits or licenses. Some even managed to run for a while without getting caught. Others? They lost everything.

The Gamble:

Here are just a few of the shortcuts I’ve seen over the years:

- Building entire facilities without building permits.

- Making major equipment changes without approval.

- Operating without health department permits.

- Selling wholesale products without a processor license.

At first glance, skipping the red tape might feel like saving time and money. But here’s the truth: when things go wrong — and they often do — the cost of fixing mistakes is far higher than doing it right the first time.

The Reality Check:

- Wasted Investments: I’ve seen businesses spend $50,000+ on construction, only to be told to tear it out and start again.

- Fines & Penalties: Civil fines can be steep, and time spent shut down is money lost.

- Insurance Risks: If an outbreak or injury happens while you’re operating without the right approvals, your insurance may not cover you.

- Lost Trust: Regulators don’t forget. Once you’re on their radar, every future inspection will be tougher.

Sure, some businesses “get away with it.” But ask yourself: Is it worth gambling your entire business on luck?

Closing Thought:

In food service, “doing the right thing” isn’t just about compliance — it’s about protecting your investment, your customers, and your future. The process may feel slow, but generally it’s cheaper and safer than shortcuts.

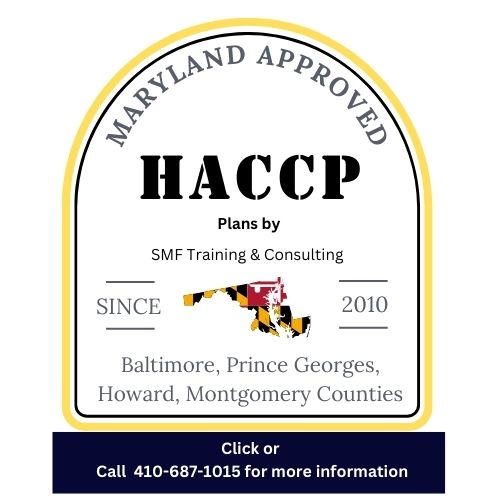

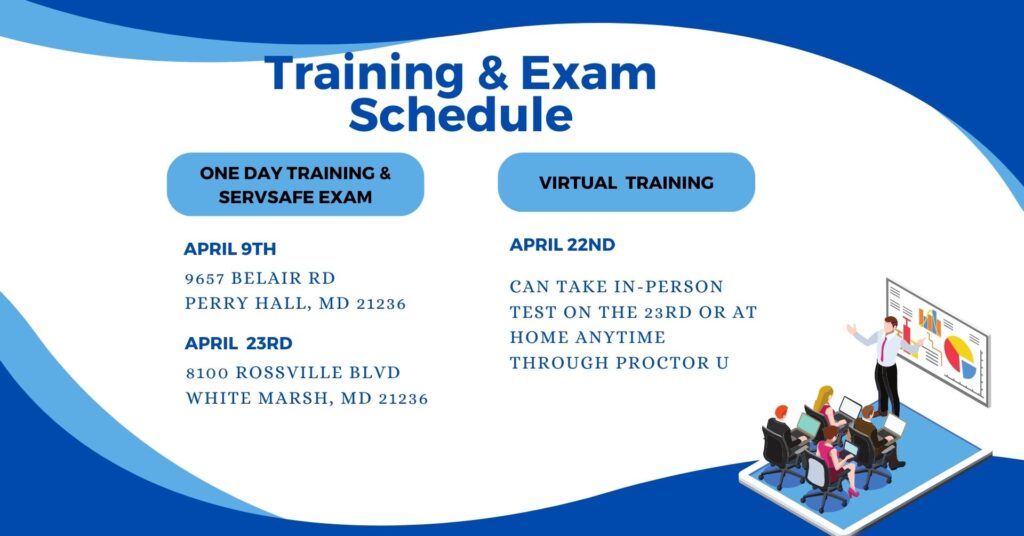

If you’re planning to expand, remodel, or launch a new product line, reach out before you break ground. The right guidance today could save you from costly regrets tomorrow.